Wavelength stabilized fiber-coupled laser modules for DPSS and fiber laser pumping

M. Hemenway, Z. Chen, M. Kanskar, W. Urbanek, D. Dawson, L. Bao, M. DeVito, K. Fortier, R. Martinsen, K. Welch, R. Ballaban, "Wavelength stabilized fiber-coupled laser modules for DPSS and fiber laser pumping," Proc. SPIE 11262, High-Power Diode Laser Technology XVIII, 112620I (2 March 2020); doi: 10.1117/12.2547539

Event: SPIE LASE, 2020, San Francisco, California, United States

Abstract

It is well documented that increases in pump module power enables higher power DPSS or CW fiber lasers, but it is important to recognize that increasing the efficiency by which the DPSS or CW fiber laser is pumped drives down both system complexity and cost. Additionally due to the narrow absorption band of the common laser mediums like Ytterbium and Neodymium, it is advantageous to maximize the spectral overlap between the emission of the pump module and the absorption band of the host medium; one way to accomplish this is by the use of Volume Bragg Gratings (VBGs) to both narrow and stabilize (meaning to minimize change with current and/or temperature) the emission of the diode pump module. To this end, we report on the continued progress by nLIGHT to develop and deliver the highest efficiency wavelength-stabilized, diode-laser pumps using single-emitter technology at ~885nm for neodymium DPSS pumping, and 969/976 nm for ytterbium laser pumping. The basis for these improvements is the ensuring the epitaxial structure of the laser diode is optimized not only for efficiency and power but is also properly optimized to minimize the amount of spectral shift with current. Due to the proprietary nature of our epitaxial structures, we are unable to provide exact details. However, throughout this paper, we will abstractly discuss the improvements made to our epitaxy, and how those changes directly affect, and improve upon the module level performance with VBGs, and provide COS and module level results for our element® packages with VBGs to support these claims, with key examples being: at 969/976 nm a 2×6 module with 140 W into 105 µm – 0.16 beam NA, and a 969/976 nm 400 W 2×12 into 200 µm – 0.16 beam NA, along with 888 nm diode module, in a 2×12 layout outputting a maximum of 370 W with 52 % electro-optical efficiency when coupled into 200 µm – 0.18 beam NA

Key words: Diode reliability, wavelength stabilized, VBG, fiber-coupled diode laser, pump diodes, diode lifetime, life- test, brightness, fiber laser, ytterbium, efficiency

1 INTRODUCTION

In our prior paper [15] we discussed the improvements to the laser diode epitaxy which generated not only more power but reduced the voltage to significantly improve the efficiency for 976 nm devices coupling into 200 µm fiber. Over the past year we have applied variations of these epitaxial improvements across our family of laser diodes, at 920 and 976 nm for efficient 105 µm fiber coupling, at 920 and for efficient 200 µm fiber coupling, and lastly at 878.6 and 888 nm (often collectively referred to as “885” nm) for efficient 200 µm fiber coupling.

Changes to the laser diode epitaxial structure and COS (chip on submount) assembly were made to firstly reduce the voltage, which directly drives efficiency and thus reduces the junction temperature of the laser diode. By reducing the junction temperature, the laser diodes output more optical power, have less wavelength shift with operating current, which is conducive to wavelength locking with a VBG, and per the Arrhenius equation (Eq. 1) have better reliability. Before proceeding, we should define what it means to “lock” a laser diode with an external VBG. To begin with, a VBG can be thought of a mirror with a very narrow spectral window over which it reflects, while also having a very tightly controlled reflectivity percentage. The VBG is then placed after the fast-axis diode collimator (FAC) or slow-axis diode collimator (SAC) and forms an external cavity for the laser diode. The effect of the VBG on the spectral content of the laser diode is demonstrated below in Figure 1 (left) where we can see the emission of the free-running laser diode module has a peak at 973.84 nm, and a FWHM value of 3.49 nm, and after insertion of the VBG the FWHM emission spectrum has been narrowed by an order of magnitude to 0.31 nm, and the peak of the emission has been “forced” by the VBG to 975.22nm, the wavelength of the VBG itself. On the right, we can now observe how the emission centroid of the free-running laser diode module changes by ~ 0.5 nm/A, and after insertion of the VBG the shift drops to ~ 0.03 nm/A. When we consider, for example, the FWHM absorption of ytterbium is < 10 nm (centered around ~ 976 nm), we can see how this example would emit outside the 971 – 871 nm absorption spectrum of the ytterbium below 12A.

Figure 1. nLIGHT e24i module emission spectrum with and without VBG (left), and module emission centroid vs current with and without VBG (right)

Notably, per the plot on the right of Figure 1, after introduction of the VBG, the emission centroid of the laser diode now changes only ~1 nm over a 30 A range compared to the free-running wavelength shifting ~ 15 nm. The importance of this reducing in nm/A shift can be graphically demonstrated by Figure 2, where the spectral overlap between the laser diode emission without VBG (left) and with VBG (right) is compared to the absorption of ytterbium.

Figure 2. nLIGHT e24i module emission spectrum at 3A, 20A and 24A without VBG (left), and module emission with VBG (right) compared to a typical absorption spectrum of an ytterbium laser medium.

It is quickly evident from the left plot that as the current is adjusted on the laser diode module, below and above a certain current range the fiber laser efficiency will fall off rapidly as the diode emission has less overlap with the ytterbium absorption band, where on the right after insertion of the VBG the module emission has perfect emission to absorption overlap across the entire operation range of the laser diode module; this is the desired outcome.

Additionally, since the spectrum has been narrowed, all the power emitted from the laser diode module is within the FWHM of the ytterbium. This leads us to the metric that is used, called Power in Band (PiB), which is the integrated spectral power over a defined region; in most cases it is the absorption centroid of the host laser medium +/- 1.5 nm, but the particular absorption characteristics of the laser host medium can increase or decrease this range. The integrated power over (for example) a 974.5 – 977.5 nm range is usually > 95 %, with well locked modules usually having values > 98 % (the measurement contains 1 – 2 % noise).

2 Laser Diode Improvements

At Photonics West 2019 [15] we reported an improved laser diode COS design that included an improved epitaxy which resulted in a device optimized for high-current and efficient coupling into 200 µm fiber, that output 23 W at 25 A, had a peak efficiency of 67 % occurring at 10 A, and a 5% improvement in efficiency (65%) at the reliability rated setpoint of 20 A & 19.3W. The measures results comparing the new, lower voltage epitaxy to the prior generation device are in Figure 3.

Figure 3. Comparison of 976 nm COS measured results: High efficiency COS (dashed) and prior generation COS (solid) at 25 °C. COS are designed to have identical near-field characteristics for efficient coupling into 200 um fiber.

These same changes were translatable to laser diodes at 920 nm and 885 nm, and laser diodes with smaller structures that are optimized for efficient coupling into 105 µm. For the high efficiency 920 nm version optimized for coupling into 200 µm fiber, the results were nearly identical to those show above (dashed lines), but with 920 nm requiring slightly higher voltage due to the bandgap. However, the laser diodes emit slightly more power at 920 nm and the result is identical efficiency, peaking at 67 % at 12A and falling off to 65 % at the intended operating point of 20 A.

Figure 4. Comparison of 920 nm COS measured results: High efficiency COS (dashed) and prior generation COS (solid) at 25 °C. COS are designed to have identical near-field characteristics for efficient coupling into 200 µm fiber.

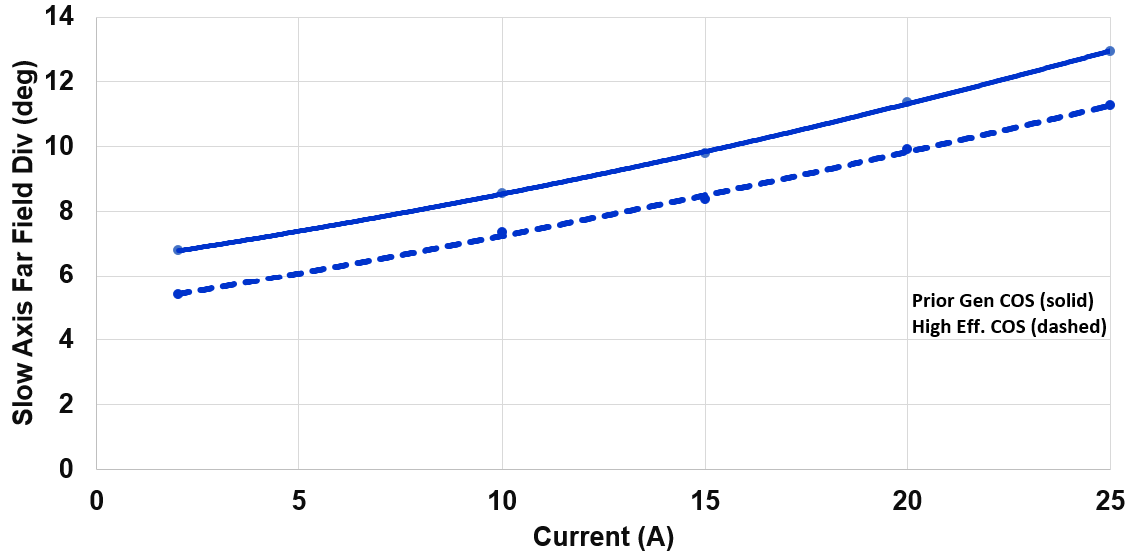

The reduced voltage, and improved efficiency have a secondary effect, and that is a reduced thermal load on the junction which results in the slow-axis far-field changing much less with current, resulting in a much brighter device; in this case approximately 13% improvement, which translates to a modest, but real improvement in module NA, with e24i (a PMUX’d 2×12 layout) module averaging 0.15 NA, where the older COS averaged 0.16 NA. The measured changes in the slow-axis far-field emission of the old and new epitaxies is shown below in Figure 5.

Figure 5. Measured results for 976 nm and 920 nm COS slow-axis far field characteristics: new high efficiency COS (dashed) and prior generation COS (solid) at 25 °C.

Additionally, the reduced thermal load on the junction has a small, but measurable improvement in the purity of the polarization of the laser diode, with a consistent ~ 1% improvement in polarization for both 920 nm and 976 nm devices, which when compared to values previously reported in [15].

These same changes to our COS were also applied to the laser diodes designed for efficient coupling into 105 µm fiber with a beam NA of ~ 0.15, resulting in similar improvements in performance. However, most notable is when the epitaxial changes were applied to our devices at 885 nm for coupling into 200 µm fiber. Efficient laser operation at 88x nm is already challenging, however the changes made to reduce the device voltage resulted in about a 0.1 V reduction, which in turn at the rated operating current of 14A calculates to a 5 % improvement in efficiency, raising from 57 % to a little over 62 %.

Figure 6. Comparison of 885 nm COS measure results: High efficiency COS (dashed) and prior generation COS (solid) at 25 °C. COS are designed to have identical near-field characteristics for efficient coupling into 200 µm fiber.

In addition to the improvement in COS performance at 885 nm, the average polarization for the new COS has increased by ~ 5 % over the prior generation COS, and due to the lower junction temperature the wavelength shift with current has been reduced by ~ 10%, moving from 0.55 nm/A to 0.5 nm/A, which has the effect of increasing the overall current range by which you can stabilize the output spectrum of the diode with the VBG. Of note, since the junction of the laser diodes was running approximately 5 °C cooler due to the lower voltage and improved submount, the Arrhenius equation,

can be used to predict the relative reliability of the two devices with respect to each other. In this exercise the variables in equation (1) are m=n=2, an activation energy (Ea) of 0.45 eV, the junction temperature (Tj) was calculated for each device (as a function of current), P is the power density, I is the current density, and kB is Boltzmann’s constant. For each of the devices discussed above, even though the devices are outputting more power, due to the junction temperature being approximately 5 °C cooler at the rated current for each device, this results in a (conservative) reliability improvement of at least 5 % across all the devices manufactured with the new epitaxial structure.

3 LASER DIODE MODULE RESULTS WITH NEW COS

Building upon last year’s [15] 400 W result, utilizing a polarization multiplexed (PMUX’d) 2×12 arrangement of COS coupled into 200 µm – 0.16 NA at 976 nm, we have productized a 920 nm version of the same 2×12 arrangement for ytterbium fiber laser pumping. The 920 nm module, due to the slightly higher power at the 920 nm wavelength resulted in production-built modules averaging 420 W (Figure 6 – dashed lines) when coupled into 200 µm – with an average measured beam NA of 0.15, when operated with the laser diode module case held to 35 °C. Additionally, these modules have excellent efficiency, averaging 53 % at their rated operating point of 20 A. However, many report performance at 25 °C, and at that condition these modules measured 465 W and 60 % efficient at 20 A (Figure 7 – solid lines)! The element® e24i module has a footprint of 59 mm x 125 mm, or about the same footprint as an iPhone 8.

Figure 7. Average measured results for 920 nm, 24-emitter modules, coupled into 200 µm fiber. Performance with module at 35 °C (dashed) and 25 °C (solid).

These same changes were also applied to the 976 nm COS design for coupling into 105 µm – 0.15 NA, and wavelength stabilized with a VBG. The changes to reduce the voltage of the COS resulted in our 105 µm device efficiency improving by 6 %, the polarization purity improving by 1 % and the nm/A reducing by 8 %. When assembled into a PMUX’d 2×6 arrangement, this netted a 10 % improvement in power at the 15 A, and a 6 % improvement in electro- optical efficiency (at the module level). Additionally, as depicted below, the overall range by which the module remained locked, that is with the Power in Band > 95 % within a spectral range of 975 – 977 nm is nearly 3x for modules with the new COS.

Figure 8. Average measured results for production built 976 nm, 12-emitter module, coupled into 105 µm fiber with a beam NA of 0.155. Performance with new COS (dashed) and old COS (solid).

Next, new COS with the high-efficiency epitaxy were fabricated at 885 nm and built by engineering into 24-emitter modules with 200 µm fiber. These modules output 265 W with 52 % efficiency at 13 A after VBG insertion, we believe a new record for VBG-stabilized modules at this wavelength. Our intention is to productize this configuration over the coming year. It should be noted the new COS has enabled us to achieve 85 W more power and 8 % higher efficiency than our previous generation of device. Also, we monitor the temperature of the proximal fiber assembly, where the light is focused into the fiber, as it is a convenient metric for fiber coupling efficiency. In the case of these modules, all the modules built had less than a 1 °C rise in temperature, relative to the module, implying a fiber coupling efficiency of > 95 % and probably closer to 99 %.

Figure 9. Average measured results for production built 888 nm, 24-emitter module, coupled into 200 µm fiber with a beam NA of 0.18, VBG-stabilized, high-efficiency COS.

4 e18 & e24i PACKAGE LIFESTEST UPDATE

In 2016 [15] we reported on the development of a 250 µm broad are laser diode (BAL) for 885 nm solid state pumping, which exhibited increased VBG locking range, and improved reliability compared to nLIGHT’s older devices, and last year [17] we provided updates for the 885 nm modules, with slightly accelerated conditions, with the modules operating at 15 A and 32 °C, compared to the nominal operating condition of 13 A and 30 °C. Per the Arrhenius equation (1), this condition amounts to ~ 2.2x acceleration, due to the increase in junction temperature from the increased operating current and temperature, and due to the increased power density on the front facet of the laser diode. Over the last three years, we have accumulated over 26k hours on each of the four e18 modules, and 2000 hours on 22 different modules through the rotating life test, resulting in 142k module hours, and 5.6M accelerated laser diode hours, with zero package failures during this time, and only three COS failures, and these 3 early COS failures are the same ones that were reported on last year, amounting to a calculated 534 failures per billion device-hours (FIT). Additionally, the long-term life test modules are removed every few thousand hours and retested, and none have exhibited any degradation in their power in band, VBG-locked performance.

Figure 10. Normalized power for four 175 W, VBG stabilized 885 nm element e18s with 200 m-0.22 NA fiber, tested at 15 A and 32 ˚C package temperature.

Three of the four modules depicted in the plot above exhibit stable power over time, with SN DPLQR having a step function at approximately 1800 hrs. due to a single COS failing. However, unlike the other modules, SN JABLO is exhibiting a slow decay, which best fits to a ln function, and predicts the module will be down to 90 % of its original power at approximately 45,000 hours of operation. We are uncertain what is causing the slow degradation, and we are hesitant to interrupt the current test to determine root cause.

In parallel a similar test is being conducted for the new element e24i module, operating at 20A and 976 nm. Last year we reported on six modules are on life test at 20 A, 35 °C, which is amounts to an acceleration factor of 1 (no acceleration), for a combined total of 19,887 accumulated module hours and 473,149 device hours on the COS, with 3 failures resulting in a COS FIT of 6340. With the implementation of the new COS containing the higher efficiency epitaxy, this lifetest was shut down and those modules were replaced with new ones populated with the new COS. In the figure below we present the lifetest data for the four modules that have been running continuously for over 5k hours at 20 A, 35 °C, which is an acceleration factor of one. As shown below, you can see there have been no module or COS failures over the combined 32k module hours and 760k COS hours.

Figure 11. Normalized lifetest power for four 375 W, 976 nm element e24i with 200 m-0.22 NA fiber, tested at 20 A and 35˚C package temperature.

5 HIGH POWER 793 nm DIODE PUMP FOR THULIUM FIBER LASERS

Lastly, although not VBG-stabilized, it is related to the topic at hand, efficient pumping of fiber lasers. We have developed a new 793 nm pump using our element e24i module, coupling two banks of 12-emitters into 200 m fiber with a beam NA of 0.16 when measured at the 95 % power enclosure point. We have not yet applied the epitaxial changes to the 793 nm devices, but with the reduced optical loss of the e24i module, this enables us to have slightly better fiber coupling efficiency and thus slightly better electro-optical efficiency. Below in Figure 12, is the average values reported for the measured power and efficiency of the e24i modules built by production. Additionally, direct temperature measurements of the of the proximal fiber assembly result in an average difference in temperature is ~ 1.6 °C, implying the fiber coupling efficiency is better than 95 % (and probably closer to 98 %). Lastly, it should be noted this this a 60 W increase in power and a 3 % increase in efficiency compared to our previous e18 (2×9) module and the element® e24i module has a footprint of 59 mm x 125 mm, resulting in not only high power and efficiency, but also excellent laser power per unit volume.

Figure 12. Average of the measured power and efficiency for production built 793 nm e24i modules.

6 CONCLUDING REMARKS

nLIGHT continues to drive innovation in multi-emitter diode modules, as demonstrated by successfully reducing our laser diode voltage by means of a revised epitaxy across multiple wavelengths, and then demonstrating module level results of these new devices by successfully productizing 465 W with a beam NA of 0.16 at 920 nm, in a 24-emitters module with 200 m fiber, and also achieving 265 W at 53 % efficiency with VBG stabilized 885 nm devices in 24- emitter module coupled into 200 m fiber, all while measuring an extremely broad locking range. Finally, the demonstrated results of our highly polarized laser diodes and high fiber-coupling efficiency with stable long-term life test results, support to our attention to DFx principles for robust and reliable products.

REFERENCES

B. Volodin, S. V. Dolgy, E. D. Melnik, E. Downs, et al, "Performance enhancement of high-power laser diodes and arrays by use of volume Bragg grating technology", Proc. SPIE 5711 (2005)

S. R. Karlsen, R. K. Price; M. Reynolds, A. Brown, R. Mehl, S. Pattern, R. J. Martinsen, “100-W, 105-µm, 0.15 NA Fiber Coupled Laser Diode Module,” Proc. of SPIE 7198, (2009).

K. Price, S. Karlsen, P. Leisher, R. Martinsen, “High Brightness Fiber Coupled Pump Laser Development,” Proc. of SPIE 7583, (2010).

Gapontsev, D., “6 kW CW single mode Ytterbium fiber laser in all-fiber format,” Proc. Solid State and Diode Laser Technology Review, 1 (2008).

W. Hu, F. D. Patel, M. L. Osowski, R. Lammert, S. W. Oh, C. Panja, V. C. Elarde, et. al, “High-spectral brightness pump sources for diode-pumped solid state lasers”, Proc. of SPIE 7198, (2009)

H. Yu, et. al., “1.2-kW single-mode fiber laser based on 100-W high-brightness pump diodes,” Proc. Of SPIE 8237, 8237-45 (2012).

Iyad Dajani, Clint Zeringue, Chunte Lu, Christopher Vergien, Leanne Henry, and Craig Robin,” Stimulated Brillouin scattering suppression through laser gain competition: scalability to high power,” Optics Letters, Vol. 35, 3114 (2010).

W. Sun, et al., “Higher brightness laser diodes with smaller slow axis divergence,” Proc. of SPIE 8605, (2013)

K. Price, M. Hemenway, L. Bao, J. Bai, K. Hoener, K. Shea, D. Dawson, M. Kanskar, “High brightness fiber coupled pump modules optimized for optical efficiency and power,” Proc. of SPIE 8605, (2013).

M. Hemenway, W. Urbanek, K. Hoener, K. Kennedy, L. Bao, D. Dawson, E. Cragerud, “High-Brightness, Fiber- Coupled Pump Modules in Fiber Laser Applications,” Proc. of SPIE 8961, (2014).

H. Yu, Y. Liu, A. Braglia, G. Rossi, G, Perrone, “Investigation of collimating and focusing lenses’ impact on laser diode stack beam parameter,” Applied Optics, Volume 54, No 34, p. 10240 – 10248 (2015).

E. Zucker, D. Zou, L. Zavala, H. Yu, P. Yalamanchili, et al, “Advancements in laser diode chip and packaging technologies for application in kW-class fiber laser pumping,” Proc. of SPIE Vol. 8965, (2014).

M. Hemenway; W. Urbanek; D. Dawson; Z. Chen; L. Bao; et al, “Advances in high-brightness fiber-coupled laser modules for pumping multi-kW CW fiber lasers,” Proc. of SPIE Vol. 10086, (2017).

M. Kanskar, L. Bao, Z. Chen, D. Dawson, M. DeVito, et al, “Continued Improvement in Reduced-mode (REM) Diodes Enable 272 W from 105 µm 0.15 NA Beam,” Proc. of SPIE Vol. 10086, (2017).

M. Hemenway, Z. Chen, W. Urbanek, D. Dawson, L. Bao, et al, “Continued advances in high-brightness fiber- coupled laser modules for efficient pumping of fiber and solid-state lasers”, Proc. Of SPIE Vol. 10514 (2018).

M. Hemenway, L. Bao, M. Kanskar, M. DeVito, W. Urbanek, et al “Performance improvements to wavelength stabilized high power 885nm diode laser modules”, Proc. of SPIE Vol. 9730, (2016)

M. Hemenway, L. Bao, M. Kanskar, M. DeVito, W. Urbanek, et al “976nm high brightness fiber-coupled laser modules for ytterbium fiber laser pumping”, Proc. of SPIE Vol. 10900, (2019)

P. Leisher, E. Feigenbaum, R. Swetfeger, . Noisselle, et al “Does collimation reduce the lifetime of broad area diode laser pumps?”, Proc. Of SPIE Vol. 10899 (2019)