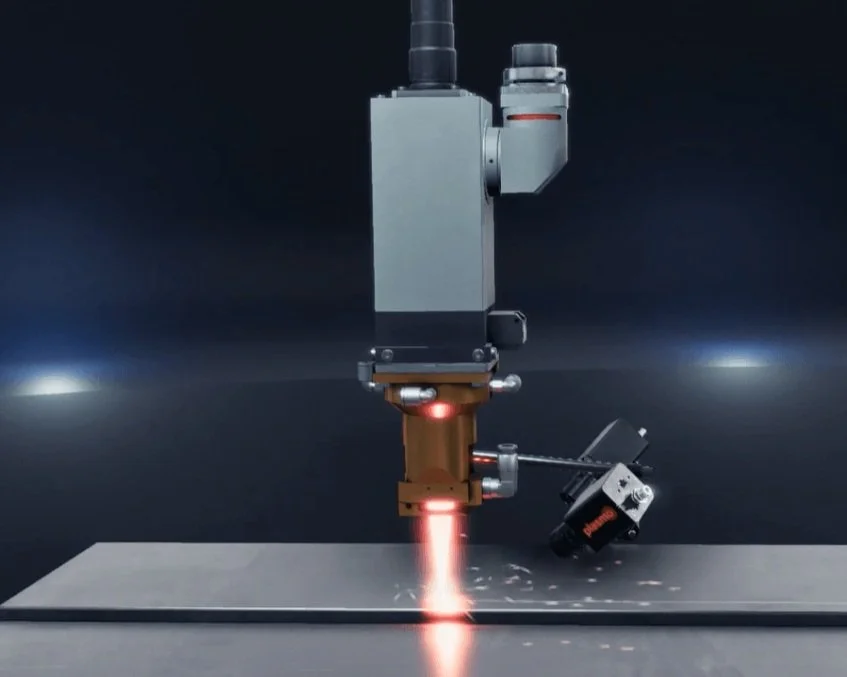

Process Monitoring

Innovative Solutions for Automated Production Processes

Plasmo has led the industry for 20 years in the field of process monitoring and quality assurance solutions. nLIGHT is proud to revive the legacy with a continued focus on world-class products and service.

Produce Quality. Always.

nLIGHT's plasmo process monitoring systems are designed to increase the productivity & quality of manufacturing processes. Our proprietary sensors and software algorithms evaluate component quality before, during, and after the welding process to ensure the strictest compliance to manufacturing requirements for automotive, aerospace, ship-building, power and similar mission-critical applications.

Flexible Solutions.

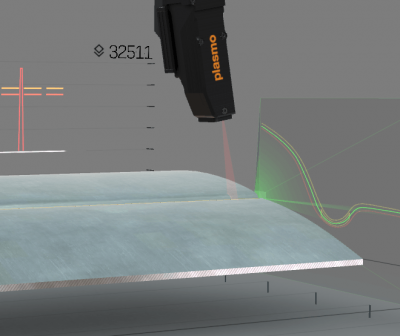

We understand that complex parts require a flexible manufacturing system, and for that we've developed a suite of sensors, data storage solutions, software, and offline tools for seamless integration with your equipment. Count on us to tailor our solution to meet your needs.

Optimum Process Monitoring.

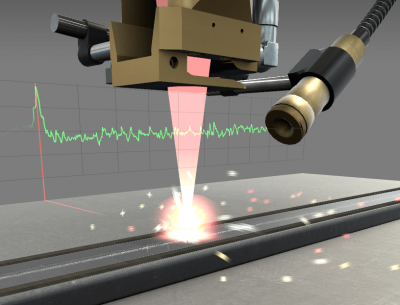

To decrease cycle time and lower production costs, we perform real-time testing and ok / not okay quality results that eliminate subsequent processes and laboratory analysis. Offline, we provide powerful data analytics software to identify manufacturing defects and to accelerate the root cause determination.

Process Monitoring for Laser Welding

In this case study you will learn how our customer monitors airbag gas generators and detects, visualizes and evaluates welding defects.

High Speed Monitoring for EV Battery

In this webinar you will learn how we have managed to cope with the growing complexity and speed to increase productivity and reduce downtimes.

Monitoring & Data Analysis for Arc Welding

In this white paper you will learn how to ensure welding quality for arc welding one of the world‘s most widely used method of joining metal.